Complete Guide to Single Pole Tower Installation: Safe and Efficient, Detail First

一、Fine preparation before the installation of the monopole tower

(一) Gain a deeper understanding of the structural characteristics of monopolar towers

Monopolar towers, as key supporting structures in transmission lines, typically have a unique appearance and complex internal structure. From the appearance, it mostly appears as towering columns with simple and smooth lines to adapt to different geographical environments and power transmission needs. The cross-sectional shape of the tower body is commonly circular or polygonal, such as a circular monopole tower with uniform force distribution, which can effectively resist lateral wind force; Polygonal monopole towers have more advantages in handling connection nodes, making it easier to assemble and fix components.

In depth exploration of its structure reveals that the monopolar tower is mainly composed of the tower base, tower body, cross arm, and attached connecting components. The tower base is the foundation of the entire structure, responsible for bearing the huge weight of the tower body and evenly dispersing it to the foundation. Its design needs to be accurately calculated based on geological conditions, tower height, and load factors, and is often poured with reinforced concrete to ensure stability and reliability. The tower body is like the backbone of the human body, usually made of high-strength steel or composite materials and assembled in sections. Each section of the tower body is equipped with reinforcing structures such as stiffeners and partitions to enhance its bending and compression resistance. As a key part of hanging wires, the cross arm extends outward and needs to have sufficient strength and rigidity. Its structural form varies depending on the voltage level of the line and the arrangement of the wires, and can be single arm, double arm, or even multi arm.

Thoroughly understanding the structural characteristics of a monopolar tower is crucial for installation work. It is like a precise blueprint before construction, which can help construction personnel predict installation difficulties in advance, plan the construction process reasonably, ensure that each component can be accurately positioned during the installation process, and that each connecting part is closely matched, laying a solid foundation for stable operation in the future.

(二) Accurate survey and processing of site and foundation

Site investigation is the vanguard of single pole tower installation, which is crucial to the success or failure of the entire project. Firstly, the investigation of terrain and landforms should not be underestimated. With the help of high-precision surveying instruments, the flatness of the installation site is finely measured, and data such as slope and height difference are recorded. For mountainous areas with large undulations, a leveling plan should be planned in advance to ensure a stable foothold for the tower foundation; At the same time, pay attention to the distribution of obstacles around the site, such as buildings, trees, etc., and plan the lifting route and equipment parking area reasonably to avoid collisions during installation.

Geological condition survey is a crucial step. Through geological drilling, geophysical exploration, and other methods, gain a deep understanding of the type, thickness, bearing capacity, and groundwater level of underground soil layers. If the site is located in soft soil layers, foundation reinforcement measures such as pile driving and replacement filling should be considered to prevent tower settlement; In rock formations, appropriate foundation anchoring methods should be designed based on the characteristics of the rock to ensure a tight connection between the tower base and the rock mass.

The basic construction strictly follows the design specifications and standards. When pouring concrete foundation, accurately control the proportion of raw materials to ensure that the concrete strength meets the standard; The vibration process is uniform and dense, eliminating defects such as honeycombs and rough surfaces. Real time monitoring of basic parameters such as size, elevation, and verticality, with errors controlled within a very small range. After construction is completed, each item is checked according to acceptance standards to create a solid foundation for the standing of the single pole tower.

(3) Thorough preparation of installation tools and materials

Sharp tools make good work. The commonly used tools for installing a single pole tower include lifting equipment, ropes, measuring instruments, etc. Lifting equipment such as cranes and tower cranes should be selected reasonably based on the height, weight, and site conditions of the single pole tower. Before installation, their mechanical performance and safety devices should be comprehensively inspected to ensure a smooth and reliable lifting process; Rope types include steel wire ropes, slings, etc. Carefully inspect for any damage or broken wires, whether the load-bearing capacity meets the requirements, and whether the specifications and models of the steel wire ropes are suitable for the corresponding working conditions. Measuring instruments such as theodolites, level gauges, total stations, etc. are used for positioning, verticality correction, and accuracy calibration during installation to ensure accurate measurement data.

The quality control of installation materials is equally crucial. Tower materials are mostly steel, and strict inspection of their material reports is required to check whether the strength, toughness, and other indicators are compliant; The appearance inspection of tower materials should not have any defects such as deformation, rust, cracks, etc. The galvanized layer should be intact and the anti-corrosion ability should be enhanced. Connecting components such as bolts, nuts, and washers, with specifications matching tower materials, strength grades meeting standards, accurate quantity counting, to avoid shortages during installation and delays in the project schedule. Thoroughly prepare installation tools and materials to provide a solid guarantee for the smooth assembly of the single pole tower.

二、Key steps control in the installation of a single pole tower

(一) Rigorous and orderly ground assembly process

Ground assembly can be regarded as the cornerstone of single pole tower installation, and its accuracy is directly related to subsequent lifting and overall structural stability. At the beginning of assembly, construction personnel need to carefully classify various tower materials according to the design blueprint and place them in the designated assembly area step by step to ensure convenient and accurate material retrieval. When assembling each section of the tower body, strictly follow the order from bottom to top, with main materials first and auxiliary materials later, building blocks layer by layer to ensure structural stability.

During the process, high-precision measuring instruments are used to monitor the assembly accuracy of each component, and the bolt tightening process is particularly critical. According to the torque value required by the design, use a torque wrench to tighten the bolts one by one to ensure a tight and reliable connection. The length of the exposed nut of the screw is precise and meets the standard, eliminating the risk of loosening and casting a rock solid foundation for the tower body, enabling it to stand proudly and bear the heavy responsibility of power transmission.

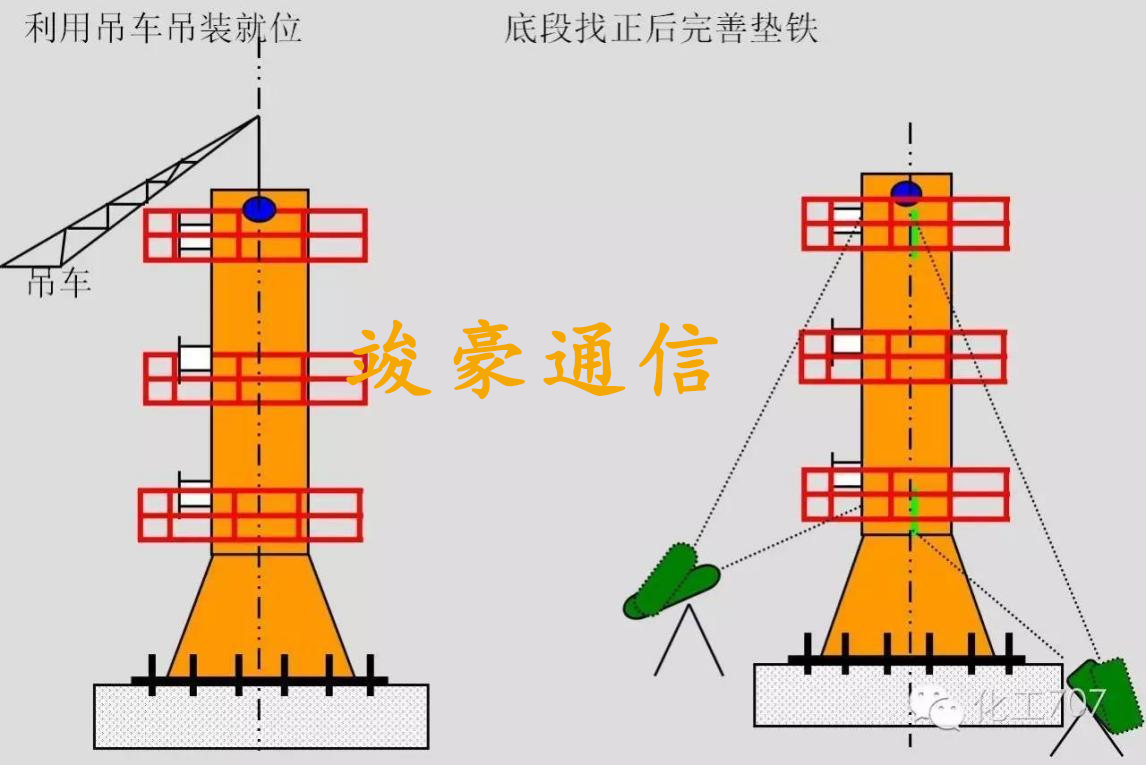

(二) Safe and efficient operation of tower hoisting

The lifting of the tower body is the highlight of the installation of a single pole tower, with risks and challenges coexisting. Before lifting, conduct a comprehensive "physical examination" of the mechanical performance of the crane, from the engine, hydraulic system to the braking device, to ensure that everything is foolproof; Carefully inspect the wear and deformation of lifting equipment such as wire ropes and hooks, and ensure that their load-bearing capacity exceeds the lifting requirements.

Carefully select suitable cranes based on the weight, height, and site layout of the tower, and accurately determine their positioning to ensure a reasonable lifting radius and ample working space. During lifting, the commanding personnel and crane driver cooperated seamlessly, using clear instructions such as flags and whistles to smoothly operate the crane and slowly lift the tower off the ground. During the process, always pay attention to the posture of the tower body, skillfully adjust it with a sliding rope to ensure its vertical rise, precise positioning, and seamless fit with the installed parts, providing protection for the "growth" of the monopolar tower.

(3) Key points for fine installation of ancillary facilities

Although the ancillary facilities seem to be supporting role, they play a key role in supporting the function of the monopole tower. Taking the installation of antenna brackets as an example, based on communication or monitoring requirements, the installation height and azimuth angle of the bracket on the tower body are accurately positioned, with an error controlled within millimeters, ensuring smooth and unobstructed signal transmission and reception. The connection between the bracket and the tower body adopts high-strength bolts and is equipped with anti loosening gaskets to resist wind and rain invasion, equipment vibration, and stably support the antenna equipment.

For maintenance platforms, ladders, and other facilities, strict control should be exercised over the welding quality during installation. The welding points should be full and firm, and the height and spacing of the handrails should comply with ergonomics and safety regulations, providing a safe and convenient passage for operation and maintenance personnel. The installation position of the aviation obstacle lights is prominent, unobstructed, and the wiring is correct to ensure stable illumination at night, guiding low altitude aircraft and enhancing the comprehensive performance of the monopolar tower in all directions.

三、Important finishing work after the installation of the monopolar tower

(1) Comprehensive and meticulous installation quality inspection

The installation of the monopolar tower is completed, and a comprehensive quality inspection is underway. Starting from the measurement of the verticality of the tower body, high-precision theodolites and total stations are used to accurately observe from multiple directions, ensuring that the deviation between the tower body and the plumb line is controlled within a very small range. Once it exceeds the allowable value, the tower base is adjusted in a timely manner or professional correction equipment is used to correct it, ensuring the stable standing of the tower body.

Check the connection parts one by one, recheck the tightening of bolts, verify the torque with a torque wrench to prevent loosening; Perform non-destructive testing on welds using ultrasonic and magnetic particle inspection techniques to identify minor cracks, porosity, and other defects. If there are any hidden dangers, repair welding immediately. The ancillary facilities are also not relaxed, maintaining the platform's load-bearing capacity testing, checking the stability of the climbing ladder, and inspecting the luminous effect of the aviation obstacle lights to ensure that every detail can withstand the test, allowing the single pole tower to be put into operation in perfect condition.

(2) Scientific and standardized lightning protection grounding settings

Lightning protection grounding is the "safety shield" of a single pole tower, with extraordinary significance. In thunderstorm weather, without effective lightning protection, single pole towers are highly susceptible to lightning strikes, causing equipment damage, power transmission interruption, and even serious consequences such as fires.

Construction follows strict standards, with precise planning for the selection of grounding electrode materials, burial depth, and spacing layout. Usually, hot-dip galvanized angle steel and steel pipes are used as grounding electrodes, buried several meters deep underground at reasonable intervals to ensure that the grounding resistance meets the standard; The grounding down conductor adopts copper stranded wire or flat steel with sufficient cross-sectional area, and is reliably welded to the tower body and grounding electrode, with anti-corrosion treatment at the connection.

Regularly check the grounding resistance, use professional resistance testers, and focus on inspecting before and after thunderstorm seasons. If the resistance increases, check for problems such as corrosion of the grounding electrode and loose connection points, and repair them in a timely manner to ensure the continuous effectiveness of the lightning protection grounding system and protect the navigation of the single pole tower and surrounding facilities.

四、Security guarantee and escort throughout the installation of the monopolar tower

(一) Strict implementation of personnel safety protection

Personnel are the core element of single pole tower installation, and their safety protection is crucial. The construction personnel involved in the installation must hold certificates before taking up their posts. Special operation personnel such as crane drivers, welders, electricians, etc. must hold corresponding qualification certificates for their respective occupations, and unlicensed operations are strictly prohibited.

Throughout the construction process, personnel protective equipment is fully equipped, including safety helmets, safety belts, safety shoes, protective gloves, etc., and the quality is qualified and meets the standards. The safety helmet is securely fastened with a chin strap to prevent head injuries from falling objects from high altitude; The seat belt is hung high and used low, with a stable and reliable hanging point to prevent personnel from falling due to slipping; Safety shoes are anti slip and puncture resistant, ensuring foot safety; Protective gloves, depending on the type of operation, such as insulated gloves for welding and wear-resistant gloves for handling, effectively protect hands.

Before starting work every day, carefully inspect the integrity of protective equipment, whether the safety belt stitching is broken, whether the safety helmet is damaged, and whether the safety shoe sole is worn. If any problems are found, replace them immediately to ensure that there are no dead corners in the protection, allowing construction personnel to work with peace of mind.

(二) Maintenance of safety warnings on construction sites

At the construction site, safety warning signs are silent guardians. Various warning signs should be set up around the installation area of the single pole tower in accordance with regulations, such as "No Entry", "Beware of High Altitude Falling Objects", "High Voltage Danger", etc. They should be made of sturdy and durable materials to ensure visibility and resistance to damage.

Reasonably divide the construction site into work areas, material stacking areas, equipment parking areas, personnel access areas, etc. The boundaries of each area are clear, and fences and warning lines are used for isolation. Especially in the work area, unrelated personnel are strictly prohibited from entering; The heavy objects in the material stacking area should be stacked stably to prevent them from rolling and injuring people; The equipment parking area ensures that the equipment is parked in an orderly manner and does not hinder construction and passage.

Arrange dedicated personnel to conduct regular inspections of the site, focusing on checking whether the warning signs are intact, whether the area boundaries have been damaged, and whether there are any new safety hazards. If any problems are found, they should be promptly rectified, such as repairing damaged signs and re setting up warning lines, to ensure that the construction site is orderly and the safety risks are controllable at all times.

五、Single pole tower installation case and experience reference

(1) Analysis and Inspiration of Successful Cases

In a coastal wind power project, the installation of a single pole tower faces challenges from strong winds, high salt spray corrosion, and complex geological conditions. In the early stage, the construction team relied on high-precision geological surveys to accurately locate soft soil layers and decisively adopted cast-in-place pile foundation reinforcement to enhance the stability of the tower foundation; Innovative use of modular ground assembly in the installation process significantly reduces the time required for high-altitude operations and lowers risks; During lifting, an advanced dynamic monitoring system is introduced to control the tower's posture in real time, command the crane to operate accurately, and ensure precise positioning in one go. In the end, the single pole tower was completed ahead of schedule and has been operating stably for many years, providing stable power supply to the surrounding area. This case highlights the key significance of meticulous preparation, innovative construction methods, and real-time monitoring in the early stage for successful installation.

For example, a communication monopole tower project in the inland plateau area has an open site but high altitude and large temperature difference. The construction party adapts to local conditions, selects cold resistant and UV resistant tower materials, optimizes the ground assembly process, arranges bolt tightening periods reasonably based on temperature changes, and uses morning and evening low temperature periods to tighten bolts and compensate for the impact of daytime thermal expansion and contraction; The hoisting is selected in the early morning when the wind is stable, reducing wind resistance interference. The final verticality deviation of the single pole tower is extremely small, and the communication signal transmission is stable. This inspires us to select materials based on environmental characteristics and arrange construction nodes reasonably to ensure quality.

(2) Reflection and Warning on Failure Cases

There was once a single pole tower installation project in mountainous areas, but due to rough terrain survey in the early stage, underground caves were not accurately detected. After foundation construction, the tower foundation settled unevenly, causing the tower body to tilt. Although it was urgently repaired and straightened, it consumed huge manpower and material resources, and the construction period was delayed for several months, warning us that even the slightest negligence in site survey could lead to a major disaster.

The installation of a single pole tower on the edge of a certain city resulted in chaotic on-site management during peak construction hours. Safety warning signs were missing, materials were randomly stacked, and a worker was injured by falling tower materials; And due to the pursuit of progress, the installation and welding of ancillary facilities are not firm, and cracks appear on the maintenance platform. Subsequent repairs are time-consuming and laborious. This reminds us that we must not slack off in any aspect of construction site management, safety protection, and quality control, otherwise we will pay a painful price. Only by strictly adhering to regulations and meticulous construction can we ensure the successful installation of the single pole tower project, let it stand for a long time, and safeguard the smooth flow of power and communication.