Angle steel: a versatile player in the world of steel

Angle steel: a versatile player in the world of steel

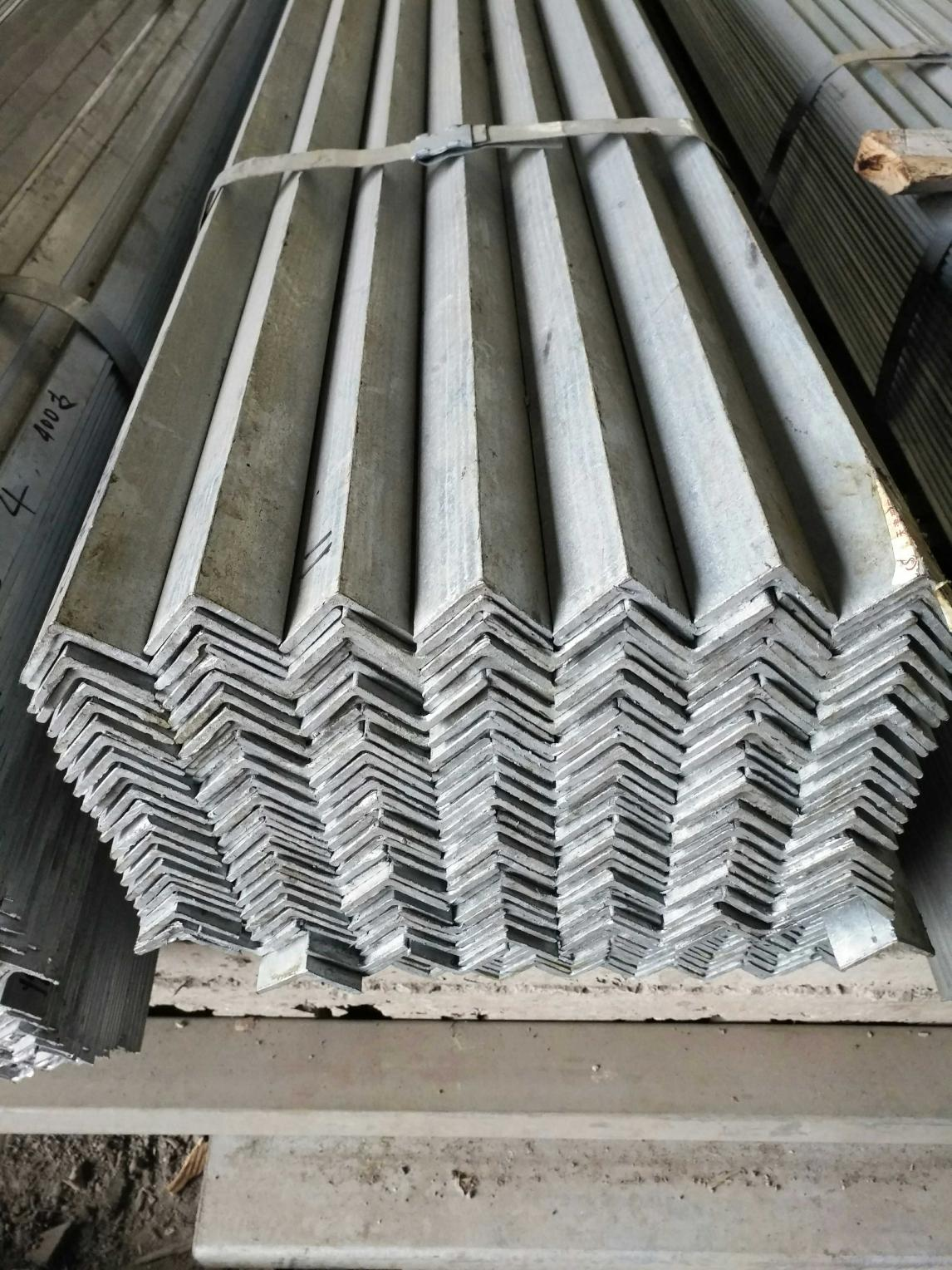

On construction sites, angle steel supports the building frame, laying a solid foundation for high-rise buildings; In the mechanical manufacturing workshop, it transforms into mechanical components to ensure stable operation of equipment; In the field of transportation, road guardrails and sign brackets made of angle steel safeguard travel safety. Angle steel, a long strip of steel with two sides perpendicular to each other forming an angle, has good supporting strength due to its unique angular structure. Under the same supporting strength, it is lighter in weight, consumes less material, and has the advantages of flexible construction and small space occupation. It is widely used in various fields such as building construction, bridges, tunnels, power towers, ships, brackets, steel structures, etc., playing a key role in supporting or fixing structures.

Angle steel is widely used and its types are also very diverse. In order to better utilize the role of angle steel in various fields, it is particularly important to understand its classification. Next, let's delve into the classification world of angle steel.

Basic classification: Equal angle steel and unequal angle steel

Equal Angle

Equilateral angle steel is a common member of the angle steel family, with equal widths on both sides, resembling a rigorous geometric shape, showcasing the beauty of symmetry. The specifications of equilateral angle steel are rich and diverse, usually expressed in millimeters of edge width x edge width x edge thickness, such as "∟ 30 x 30 x 3", which represents an equilateral angle steel with an edge width of 30 millimeters and an edge thickness of 3 millimeters; It can also be represented by the model, which is the number of centimeters of the edge width, such as ∟ 3 #. However, in practical applications, to avoid confusion, it is recommended to fill in the width and thickness dimensions of the angle steel in the contract and other documents. The specification range of hot-rolled equilateral angle steel is generally from 2 # to 20 #, covering a variety of choices from smaller models to larger ones.

In the field of architecture, equilateral angle steel can be regarded as the "cornerstone". It is widely used in key parts such as beams, columns, and frames when building building building frameworks. Taking the common multi story building as an example, the frame structure made of equilateral angle steel can withstand the huge loads transmitted from the floor and roof with its high strength and rigidity, and stably transfer these loads to the foundation, thereby ensuring the stability and safety of the building during long-term use. In some large shopping malls, sports centers, and other large-span buildings, equilateral angle steel works in conjunction with other building materials to provide reliable support for large spaces.

In the mechanical manufacturing industry, equilateral angle steel also plays an important role. It can be used to make support structures for mechanical equipment, such as machine tool bases, brackets, etc., providing a solid foundation for the stable operation of the equipment. Due to the relatively light weight of equilateral angle steel, it can reduce the overall weight of mechanical equipment while ensuring strength, thereby improving the operational efficiency of the equipment. In automobile manufacturing, equilateral angle steel can be used for the manufacturing of automobile chassis, frame and other components, to withstand various forces during the driving process of the car and ensure driving safety.

Unequal angle steel

Unequal angle steel, compared to equilateral angle steel, has the biggest feature of unequal width on both sides, which gives it a unique performance advantage. Unequal angle steel can be further divided into two types: unequal sided equal thickness and unequal sided unequal thickness. Unequal angle steel with equal thickness has the same thickness on both sides, but with different edge lengths. It is widely used in situations where specific requirements are placed on structural strength and stability; Unequal and unequal thickness angle steel has differences in thickness and length on both sides, which allows it to better exhibit material properties when subjected to complex stresses.

The specification representation method of unequal angle steel is similar to that of equilateral angle steel, expressed in millimeters of long side width x short side width x edge thickness, such as "L30 x 20 x 3", which represents an unequal angle steel with a long side width of 30mm, a short side width of 20mm, and an edge thickness of 3mm; It can also be represented by model, which is expressed as a fraction, with the numerator being the number of centimeters of the long side width and the denominator being the number of centimeters of the short side width, such as "L3/2 #". Its specification range is 2.5/1.6 # -20/12.5 #.

In the construction of special structures, unequal angle steel plays a significant role. In some irregularly shaped building structures, unequal angle steel can be flexibly spliced and combined according to design requirements to meet the special requirements of building structures for shape and mechanical properties. For example, in some uniquely shaped bridge buildings, unequal angle steel is used to make the support structure and connectors of the bridge, which can adapt to the complex stress conditions of the bridge and ensure its stability under various loads. In mechanical manufacturing, unequal angle steel is an ideal material for some mechanical components that need to withstand asymmetric forces. For example, in the design of the crane boom, unequal angle steel can be arranged reasonably according to the stress characteristics of different parts of the boom, improving the load-bearing capacity and work efficiency of the boom.

Divided by size: large, medium, and small angle steel

In the world of angle steel, dividing by size is a common and practical classification method, which can be divided into large angle steel, medium angle steel, and small angle steel. Different sizes of angle steel play unique roles on their respective "stages".

Large angle steel

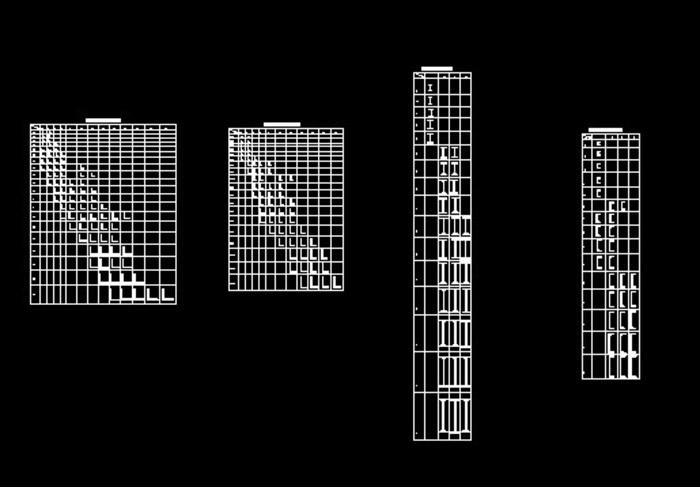

Large angle steel usually refers to angle steel with a side length of 12.5cm or more. This type of angle steel has a huge body shape, strong load-bearing capacity, and excellent stability, like a "strongman" in the fields of architecture and industry. In large-scale construction projects, large angle steel is a key material for building stable structures. For example, in the frame structure of super high-rise buildings, large angle steel is used to make the main load-bearing columns and beams, which can withstand huge vertical loads and horizontal wind forces, providing solid and reliable support for the entire building. Large angle steel also plays an important role in the manufacturing of heavy machinery. In the manufacturing of large cranes, excavators and other mechanical equipment, large angle steel is used to make the main frame and support structure of the equipment, ensuring that the equipment can operate stably in high-strength working environments and withstand various complex stresses and impact forces.

Medium sized angle steel

The side length range of medium-sized angle steel is between 12.5cm and 5cm, which combines certain strength and good flexibility, and has a wide range of applications. In general construction, medium-sized angle steel is one of the commonly used building materials. It can be used to construct roof trusses, stair handrails, door and window frames, and other parts of buildings, providing structural support and decorative functions for the building. In the construction of some small factories and warehouses, the frame structure composed of medium-sized angle steel can meet the needs of carrying goods and equipment, while having the advantages of low cost and convenient construction. In the field of equipment manufacturing, medium-sized angle steel also has many applications. For example, in the production of racks and bases for some industrial equipment, medium-sized angle steel can be flexibly processed and assembled according to the size and functional requirements of the equipment, providing a stable installation foundation for the equipment. Medium sized angle steel is also commonly used to make various pipeline supports, cable trays, etc., to ensure the safe layout and normal operation of pipeline and cable systems in industrial production.

Small angle steel

Small angle steel with a side length of less than 5cm, due to its small and flexible characteristics, exhibits unique charm in the fields of small components and decoration. In the production of small components, small angle steel is often used to make some small brackets, frames, etc. For example, in furniture manufacturing, small angle steel can be used to make the internal support structure of furniture, enhancing its stability and load-bearing capacity. In the production of shell frames for some small electrical equipment, small angle steel can also play a role, ensuring the structural strength of the equipment without adding too much weight. In the field of decoration, the application of small angle steel is even more diverse. It can be used to create various decorative lines, styling frames, etc., adding a unique style to indoor and outdoor decoration. In the production of some shop signs, small angle steel can be used to create various creative shapes of borders, making the sign more eye-catching and beautiful. Small angle steel is also commonly used to make wrought iron decorations, such as wrought iron flower stands, wrought iron ornaments, etc. Through precise processing and design, it exhibits unique artistic effects.

Process perspective: Hot rolled and cold-rolled angle steel

From a process perspective, angle steel can be divided into hot-rolled angle steel and cold-rolled angle steel. These two types of angle steel produced by different processes have their own unique "characteristics" and applicable scenarios.

hot-rolled angle steel

Hot rolled angle steel is produced by heating steel billets to high temperatures to give them good plasticity, and then rolling them through a rolling mill. During this process, high temperature causes changes in the internal structure of the steel billet, refining its grain size and endowing hot-rolled angle steel with good plasticity and toughness. Hot rolled angle steel has high strength, can withstand large loads, and has excellent processing performance. It can be processed twice through welding, cutting, and other methods to meet the needs of different projects.

In large-scale construction projects, hot-rolled angle steel is undoubtedly the "protagonist". In bridge construction, a large amount of hot-rolled angle steel is used to make the main structure of bridges, such as bridge piers and support beams. With its strong bearing capacity, it ensures the stability of bridges under various complex environments and loads. Like the world-renowned Hong Kong Zhuhai Macao Bridge, a large amount of hot-rolled angle steel was used in its construction process, providing solid material support for the smooth completion of this mega project. In the field of shipbuilding, hot-rolled angle steel is used to construct the skeleton structure of ships, withstand various stresses and impact forces of the hull during navigation, and ensure the safe navigation of ships. In the construction of industrial plants, the frame structure constructed with hot-rolled angle steel can provide stable support for large equipment and meet the needs of industrial production.

Cold rolled angle steel

The production process of cold-rolled angle steel is different from that of hot-rolled angle steel. It is formed into the shape of angle steel by cold bending steel plates or strips at room temperature. This process results in extremely high dimensional accuracy of cold-rolled angle steel, with a very smooth surface that feels like it has been carefully polished. The mechanical properties of cold-rolled angle steel are also excellent, with high strength and hardness. However, due to the complexity of the cold rolling process and the high requirements for equipment, its production cost is relatively high.

Cold rolled angle steel is commonly used in applications that require high precision and surface quality. In precision instrument manufacturing, components made of cold-rolled angle steel can meet the stringent precision requirements of the instrument and ensure its precise operation. In the field of furniture manufacturing, cold-rolled angle steel can be used to make the frame structure of furniture, and its smooth surface does not require excessive post-processing, adding a sense of refinement to furniture. In some high-end building decoration projects, cold-rolled angle steel is used to make decorative lines, shape frames, etc. Its precise size and beautiful appearance can add a lot of points to the building decoration effect. For example, in some modern commercial complexes, the unique decorative shapes made of cold-rolled angle steel attract the attention of many consumers, adding a fashionable and artistic atmosphere to the building.

Special angle steel: galvanized angle steel

镀锌工艺

Galvanized angle steel is a type of steel made by galvanizing ordinary angle steel. The galvanizing process mainly includes two types: hot-dip galvanizing and cold galvanizing. The hot-dip galvanizing process is quite common, which involves immersing the rust removed angle steel in a molten zinc solution at around 500 ℃ to attach a layer of zinc to the surface of the angle steel. In this process, the angle steel first needs to undergo acid washing to remove surface rust and impurities, followed by water washing to remove residual acid solution, then immersed in a plating aid solvent, dried and preheated, and then immersed in zinc solution for hanging plating. After completion, it needs to go through a series of processes such as cooling, passivation, cleaning, and polishing to finally obtain hot-dip galvanized angle steel. This process forms a metallurgical bond between the galvanized layer and the steel, becoming a part of the steel surface. The coating has high reliability, uniform thickness, and can reach 30-50um. It has excellent anti-corrosion performance and is suitable for various strong acid, alkali mist and other strong corrosive environments.

Cold galvanizing is a coating that uses zinc fillers to ensure sufficient contact between zinc powder and steel through electrochemical principles, generating an electrode potential difference for corrosion prevention. Before construction, it is necessary to mechanically remove rust from the steel, such as sandblasting, shot blasting, etc., to ensure that the surface cleanliness of the steel meets ISO 85O1-1 Sa 2.5 level. Different cold galvanized materials also have different requirements for surface roughness. The coating of cold galvanizing is relatively thin and is generally suitable for indoor environments or occasions with relatively low anti-corrosion requirements.

分类与优点

Galvanized angle steel can be divided into galvanized equilateral angle steel and galvanized unequal angle steel according to side length. Its specification representation method is similar to that of ordinary equilateral angle steel and unequal angle steel, except that the word "galvanized" is added in front. For example, galvanized equilateral angle steel "∟ 30 × 30 × 3" refers to galvanized equilateral angle steel with a width of 30 millimeters and a thickness of 3 millimeters; Galvanized unequal angle steel "L30 × 20 × 3" refers to galvanized unequal angle steel with a long side width of 30mm, a short side width of 20mm, and an edge thickness of 3mm.

Galvanized angle steel has many advantages. The processing cost is relatively low, and the cost of hot-dip galvanizing for rust prevention is lower than that of other paint coatings. Its anti-corrosion performance is excellent. In suburban environments, the standard hot-dip galvanized anti rust thickness of hot-dip galvanized angle steel can be maintained for more than 50 years without the need for repair; In urban or coastal areas, the standard hot-dip galvanized anti rust layer can be maintained for 20 years without the need for repair. Moreover, due to the metallurgical bonding between the galvanized layer and the steel, the reliability is excellent. Its coating also has strong toughness and can withstand mechanical damage during transportation and use. The galvanizing process is also more time-saving and labor-saving, faster than other coating construction methods, and can avoid the time required for painting on the construction site after installation. In addition, every part of the plated part can be coated with zinc, providing comprehensive protection even in concave, sharp, and hidden areas. Galvanized angle steel can be seen in many fields such as power towers, communication towers, curtain wall materials, shelf construction, railway and highway protection, street lamp poles, marine components, building steel structure components, substation ancillary facilities, and light industry.

Key points for selection and application of angle steel

In practical applications, choosing the appropriate angle steel is crucial. If it is a building structure that needs to withstand large loads, such as the main frame of high-rise buildings, priority should be given to large hot-rolled equilateral angle steel, whose high strength and good toughness can ensure the stability of the structure; For some indoor decoration projects that require high appearance and dimensional accuracy, cold-rolled angle steel is a better choice. If the project is located in a humid or corrosive environment, galvanized angle steel is undoubtedly the best choice, which can effectively extend the service life of the angle steel and reduce maintenance costs. When choosing angle steel, attention should also be paid to its quality. The surface of high-quality angle steel should be smooth and flat, without defects such as cracks, bubbles, scars, etc; The size should comply with national standards and the error should be within the allowable range.

Through in-depth understanding of different types of angle steel, we have seen the widespread application and important role of angle steel in various fields. From infrastructure construction to industrial manufacturing, from large-scale projects to fine decoration, angle steel contributes to our lives and social development with its diverse classifications and unique properties. I hope that in future work and life, everyone can accurately and reasonably choose and use angle steel according to their actual needs, so that this versatile steel industry can play a greater value.